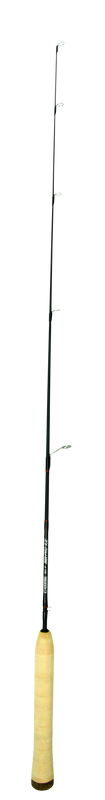

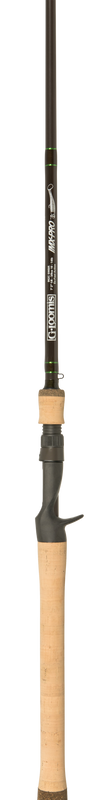

Multi-taper technology allow us to reduce weight and increase sensitivity while keeping rod balance in mind - reel attached - which is critical for success in managing drifts and detecting even the lightest bite A comprehensive selection of lengths and tapers to provide anglers with an option for the varying techniques and presentations required to be a successful steelhead angler. Providing anglers with an opportunity to experience the legendary G.Loomis performance and quality at a very reasonable price

Key Features

- High-modulus graphite construction

- Un rivaled durability + performance

- Multi-Taper Design reinforces potential stress points within the blank while reducing unnecessary graphite material

- Grade A cork handles

- Technique specific actions

- Handcrafted in Woodland, Washington

Featured Technologies

Models Available

| Sku | Model | Length | Power | Action | Pieces | Line (lb) | Lure (oz) | Handle | Price | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 12732-01 | E6X 1025-2C STR | 8'6" | Medium Heavy | Fast | 2 | 8-17 | 3/8-1 | - | $275.00 | ||

| 12736-01 | E6X 1084-2C STR | 9'0" | Medium | Fast | 1 | 8-12 | 3/8-3/4 | - | $280.00 | ||

| 12738-01 | E6X 1086-2C STR | 9'0" | Heavy | Fast | 1 | 10-20 | 3/8-1 1/2 | - | $280.00 | ||

| 12739-01 | E6X 1143-2C STR | 9'6" | Medium Light | Fast | 1 | 6-12 | 5/16-3/4 | - | $285.00 |

Technology

-

MULTI-TAPER DESIGN

Since 1982, we’ve pushed the boundaries of manufacturing technology, materials innovation, and product design. That’s why G. Loomis rods deliver superior performance, heightening angler experience and effectiveness on the water. While there are countless examples of this philosophy in action, one technology in particular encapsulates our drive to build the most advanced rods in the world: Multi-Taper Design.

Multi-Taper Design is best described as a series of “micro-tapers” within the overall taper of the rod. This unique, proprietary process allows us to use more material on potential break points and less material everywhere else. To accomplish this, we manufactured a custom rolling table...and it’s the only one in existence today. The result is a catalog of precisely defined actions that strike a perfect balance between durability and performance.